Industrija 4.0 metāla apstrādē: CNC hidraulisko cauruļu liekšanas tehnoloģijas uzplaukums

Dec.23.2025

Datu avots: Rūpniecības mašīnbūves ziņojums

Globālā metālapstrādes nozare pieredz strauju pāreju uz automatizāciju, ko virza augsta precizitātes komponentu pieaugošais pieprasījums automašīnu, aviācijas un būvniecības jomās. Vadošie ražotāji tagad demonstrē jaunākās CNC hidrauliskās cauruļu liekšanas mašīnas un Automātiskās hidrauliskās liecējmašīnas , ieviešot jaunus standartus efektivitātei un precizitātei.

🚀 Pāreja uz CNC automatizāciju

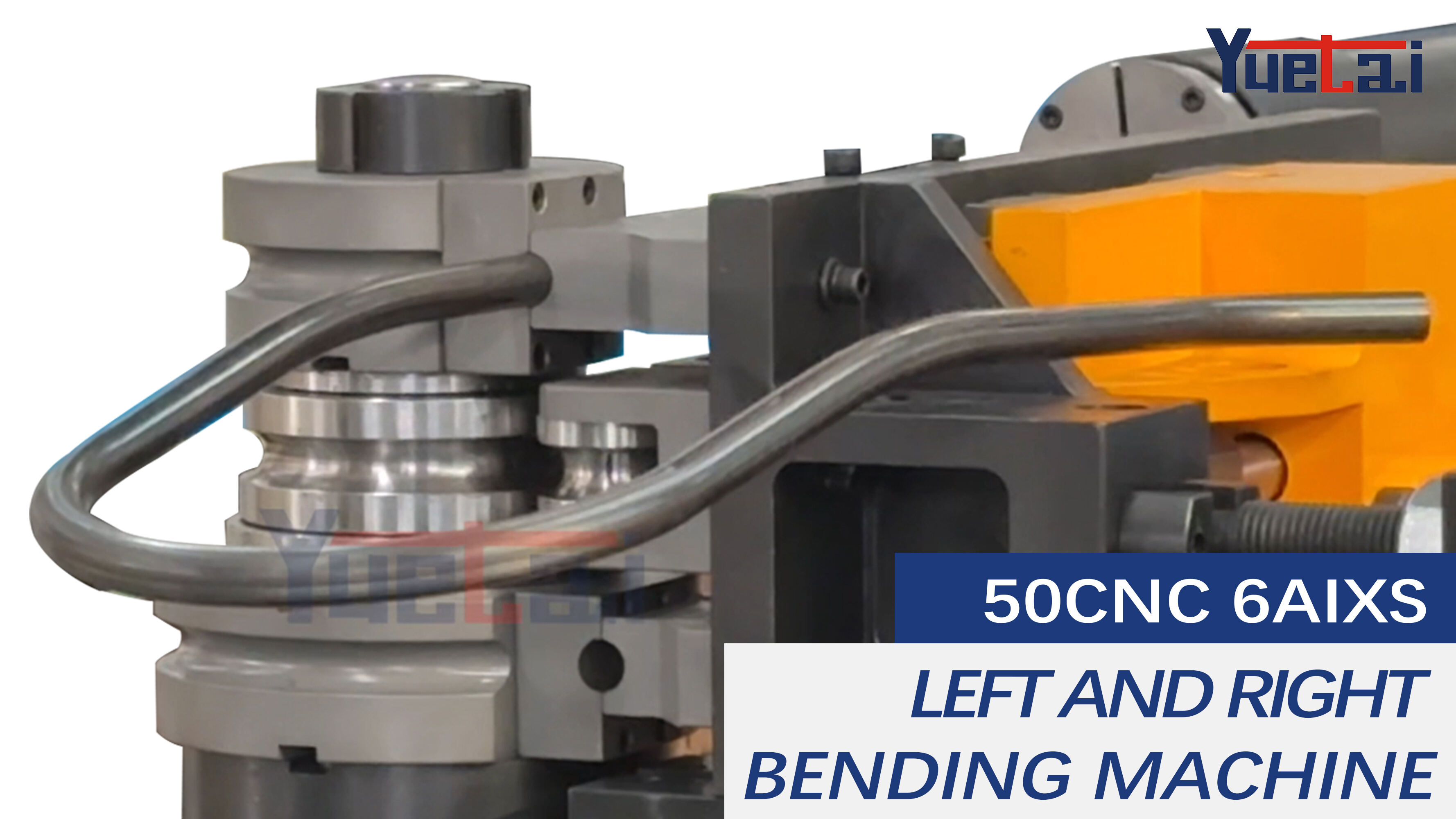

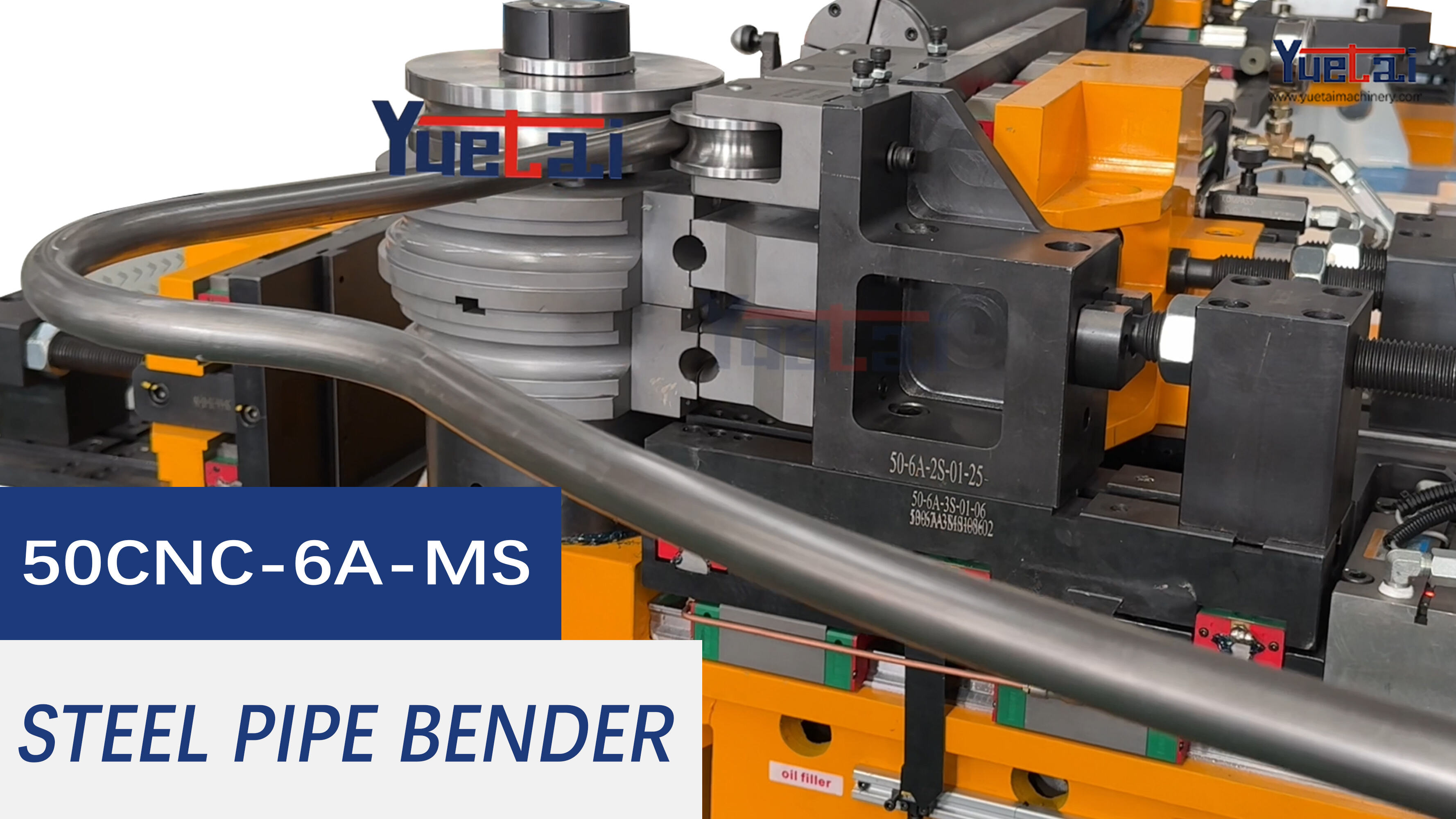

Mūsdienu apstrāde attālinās no manuālā darba, lai pieņemtu Datorvadība (CNC) tehnoloģiju. Šīs jaunās paaudzes mašīnas, piemēram, CNC automātiskais hidrauliskais cauruļu liekšanas mašīns , ļauj precīzi veidot dažādus materiālus, tostarp Oglekļa tērauds , Dzelzs , un Dozētas caurules .

Servodzinēju un hidraulisko piedziņu sistēmu integrācija nodrošina, ka šīs mašīnas spēj apstrādāt sarežģītas ģeometrijas — no vienkāršām līkumēm līdz daudzlīkņu 3D formām — nezaudējot ātrumu vai kvalitāti. Tas ir īpaši svarīgi tādās industrijās kā automašīnu ražošana, kur izplūdes sistēmām un šasijas komponentiem nepieciešama mikronu precizitāte.

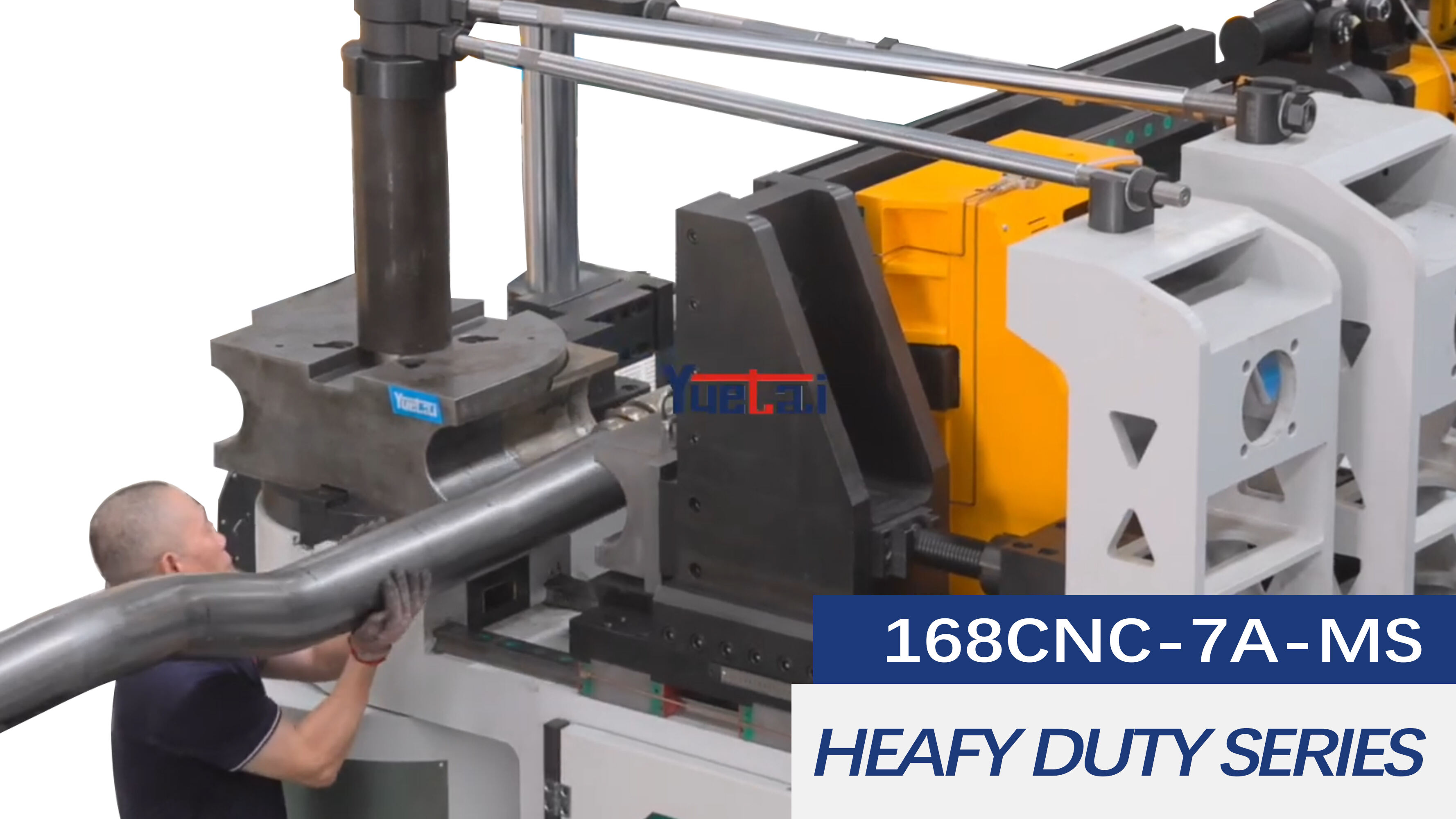

💪 Robusts inženierijas risinājums smagiem uzdevumiem

Lai gan galvenais uzsvars ir uz precizitāti, jaunākās mašīnas ir izstrādātas arī smagam darbam. Tipisks piemērs ir CNC hidrauliskā mandrelcauruļu liekšanas mašīna izmantojot hidraulisko piedziņu sistēmu kombinācijā ar izturīgu rāmi (bieži izgatavots no augsta izturības tērauda), šīs mašīnas spēj liekt biezsienu caurules ar minimālu deformāciju.

Svarīgas šo moderno sistēmu iezīmes ietver:

🌍 Tirgus tendences un drošība

Pašreizējā tirgus tendence akcentē "plug-and-play" risinājumus, kas ir gan jaudīgi, gan droši. Daudzi jaunie modeļi, piemēram, Elektriskā cauruļu liekšanas mašīna DW CNC sērija , tiek izlaisti ar CE sertifikācija , nodrošinot to atbilstību stingriem Eiropas veselības, drošības un vides aizsardzības standartiem.

| Funkcija | Priekšrocība |

| Hidrauliskais piedziņš | Augsts krējums biezu materiālu liekšanai |

| CNC vadība | Atkārtojamība un sarežģītu formu precizitāte |

| Mandreļa liekšana | Novērš rievu veidošanos un šķērsgriezuma deformāciju |

| Hidrauliskais piedziņš | Augsts krējums biezu materiālu liekšanai |

| CNC vadība | Atkārtojamība un sarežģītu formu precizitāte |

| Mandreļa liekšana | Novērš rievu veidošanos un šķērsgriezuma deformāciju |

🔮 Skatoties nākotnē

Kopš pieprasījums pēc pielāgotiem metāla komponentiem aug, šo mašīnu daudzpusība paplašinās. Vai nu tā ir Izplūdes caurule ražošana vai konstrukcijas Profilu liekšana , kombinācija no hidrauliskās enerģijas un digitālās vadības pierāda, ka tā ir rūpniecības nākotne.

M a n u f a c t u r e r s a r e n o platums o f f e r i n g t augstums e s e m a c augstums i n e s "F o r S a garums e "platums i t augstums c o m p e t i t i v e p r i c i n g ,a i m i n g t o augstums e garums p platums o r k s augstums o p s o f a garums garums s i z e s u p g r a d e t augstums e i r c a p a b i garums i t i e s a n d m e e t t augstums e r i g o r o u s d e m a n d s o f m o d e r n e n g i n e e r i n g p r o j e c t s .