- Overview

- Recommended Products

| Technical Specifications | Unit | 18 | 25 | 38 | 50 | 65 | 75 | 80 | 90 | 100 | 115 | 130 | 168 | 219 | 273 |

| Max Bending Capacity – Carbon Steel (σs = 400 MPa) | mm | φ18*1.6 | φ25*2 | φ38*2 | φ50*2.0 | φ65*2.5 | φ75*2.5 | φ80*2.5 | φ89*2.5 | φ100*2.5 | φ114*5 | φ130*5 | φ168*15 | φ219*16 | φ270*20 |

| Max Bending Capacity – Stainless Steel (σs = 600 MPa) | mm | φ15*1 | φ20*1.0 | φ32*1.2 | φ42*1.2 | φ52*1.5 | φ62*2 | φ65*2 | φ70*1.5 | φ80*1.5 | φ102*2 | φ114*2.5 | φ152*4 | φ190*10 | φ252*10 |

| Min Centerline Bending Radius (CLR) | mm | 1.5D< | 1.5D< | 1.5D< | 1.5D< | 1.5D< | 1.5D< | 1.5D< | 1.5D< | 1.5D< | 1.5D< | 1.5D< | 1.5D< | 1.5D< | 1.5D< |

| Max Capacity – Square / Rectangular Tubes | mm | 12*1.2 | 16*1.5 | 28*1.5 | 40*1.5 | 45*2 | 50*2 | 50*2.5 | 60*2.5 | 65*2.5 | 90*2.5 | 95*3 | 110*5 | 180*10 | 200*12 |

| Max Bending Diameter (Customizable with Push Bending Assist) | mm | φ10 | φ20 | φ34 | φ48 | φ52 | φ62 | φ74 | φ89 | φ98 | φ114 | φ114 | φ140 | φ190 | φ250 |

| Bending Radius Range (Min – Max CLR) | mm | 10-80 | 10-140 | 15-150 | 20-180 | 30-200 | 35-230 | 40-250 | 40-270 | 40-285 | 50-350 | 60-400 | 90-550 | 120-800 | 130-1000 |

| Max Bending Angle | degree | 190 | 190 | 190 | 190 | 190 | 190 | 190 | 190 | 190 | 190 | 190 | 190 | 190 | 190 |

| Max Center Distance Between Two Bends (R1 – R2) | mm | 30 | 40 | 65 | 65 | 75 | 85 | 100 | 110 | 120 | 130 | 130 | 145 | 170 | 180 |

| Max Feed Length with Mandrel | mm | 3000 | 3000 | 3000 | 3200 | 3500 | 4000 | 4700 | 5000 | 5300 | 5500 | 5500 | 5800 | 6500 | 7000 |

| Max Straight Length from Clamp to End (For Easy Loading) | mm | 2000 | 2000 | 2500 | 2500 | 2500 | 2800 | 2900 | 3000 | 3500 | 4000 | 4000 | 4500 | 4800 | 5200 |

| Table Height (Center of Bending Die to Floor) | mm | 1100 | 1100 | 1100 | 1150 | 1215 | 1215 | 1200 | 1305 | 1115 | 1450 | 1450 | 1470 | 1650 | 1800 |

| Bending Die Center Height | mm | 22 | 30 | 38 | 38 | 50 | 65 | 68 | 68 | 75 | 90 | 90 | 150 | 165 | 185 |

| Max Bending Speed (BOD – Bend on Distance) | deg/sec | 220 | 220 | 160 | 105 | 100 | 75 | 65 | 58 | 47 | 40 | 25 | 20 | 10 | 6 |

| Bending Accuracy (± mm or ±°) | degree | ±0.05 | ±0.05 | ±0.05 | ±0.05 | ±0.05 | ±0.05 | ±0.05 | ±0.05 | ±0.05 | ±0.1 | ±0.1 | ±0.15 | ±0.15 | ±0.2 |

| Max Feeding Speed (DBB – Distance Between Bends) | mm/sec | 2000 | 2000 | 1400 | 1400 | 420 | 400 | 360 | 360 | 360 | 260 | 260 | 240 | 230 | 215 |

| Feeding Accuracy (± mm) | mm | ±0.05 | ±0.05 | ±0.05 | ±0.05 | ±0.05 | ±0.05 | ±0.05 | ±0.05 | ±0.05 | ±0.05 | ±0.05 | ±0.1 | ±0.1 | ±0.1 |

| Max Rotation Speed (POB – Plane of Bend) | deg/sec | 300 | 300 | 300 | 200 | 200 | 200 | 240 | 220 | 200 | 170 | 170 | 140 | 100 | 80 |

| Rotation Accuracy (±°) | mm | ±0.05 | ±0.05 | ±0.05 | ±0.05 | ±0.05 | ±0.05 | ±0.05 | ±0.05 | ±0.05 | ±0.05 | ±0.05 | ±0.15 | ±0.15 | ±0.2 |

| Hydraulic Motor Power | kw | 2.2 | 4 | 4 | 5 | 7.5 | 7.5 | 15 | 15 | 15 | 22 | 22 | 30 | 45+11 | 55+11 |

| Machine Width | mm | 760 | 760 | 1150 | 1300 | 1850 | 1450 | 2100 | 2180 | 2300 | 1700 | 2000 | 2400 | 3500 | 3800 |

| Machine Height | mm | 1300 | 1300 | 1450 | 1450 | 1780 | 1400 | 1770 | 1800 | 2170 | 2100 | 2100 | 2150 | 2500 | 2700 |

| Machine Length | mm | 3500 | 4050 | 4900 | 5350 | 5800 | 6200 | 6290 | 6850 | 7800 | 7000 | 9000 | 9300 | 13500 | 15000 |

| Machine Weight | kg | 1100 | 1500 | 3000 | 3500 | 5900 | 6000 | 6700 | 7900 | 10000 | 12000 | 13000 | 16000 | 32000 | 50000 |

CNC Full Automatic Bending Machine

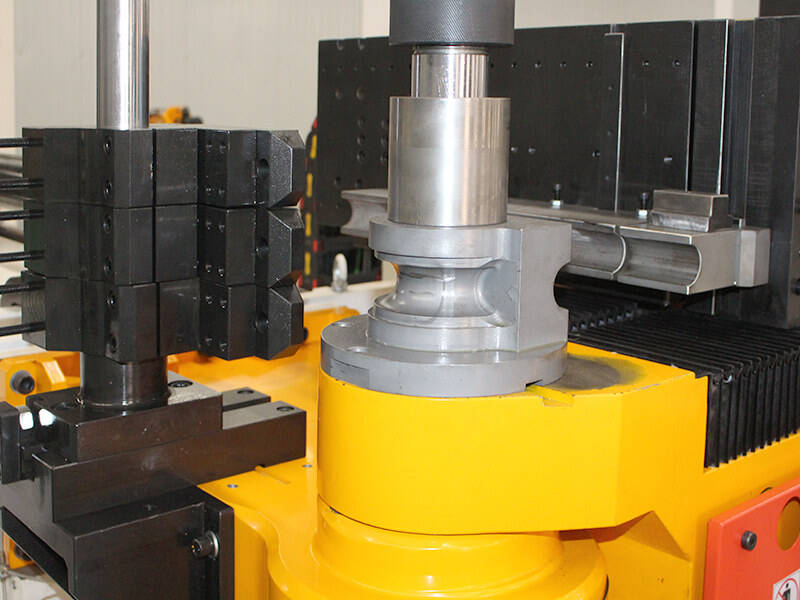

Equipped with 3 4 electric CNC axes

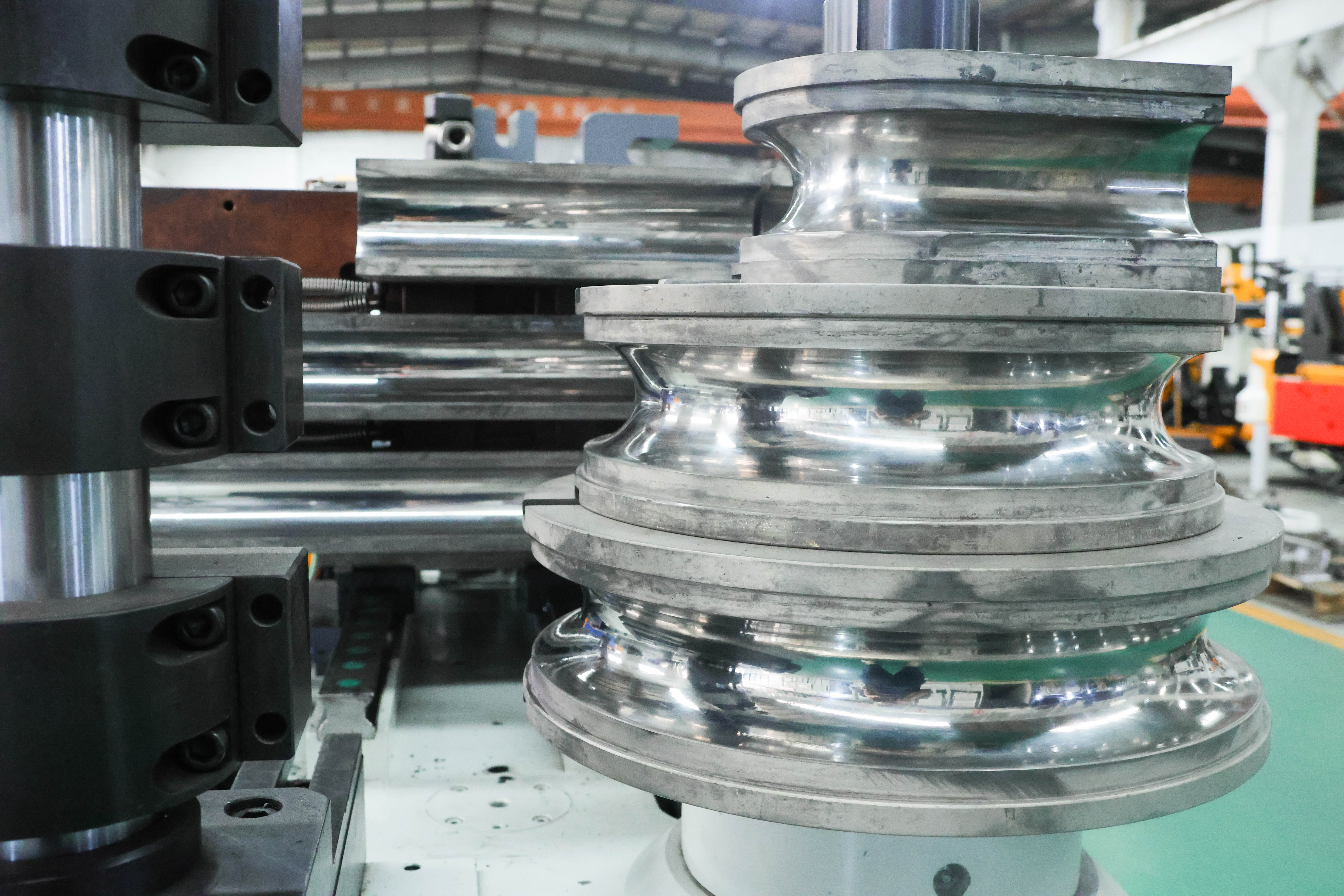

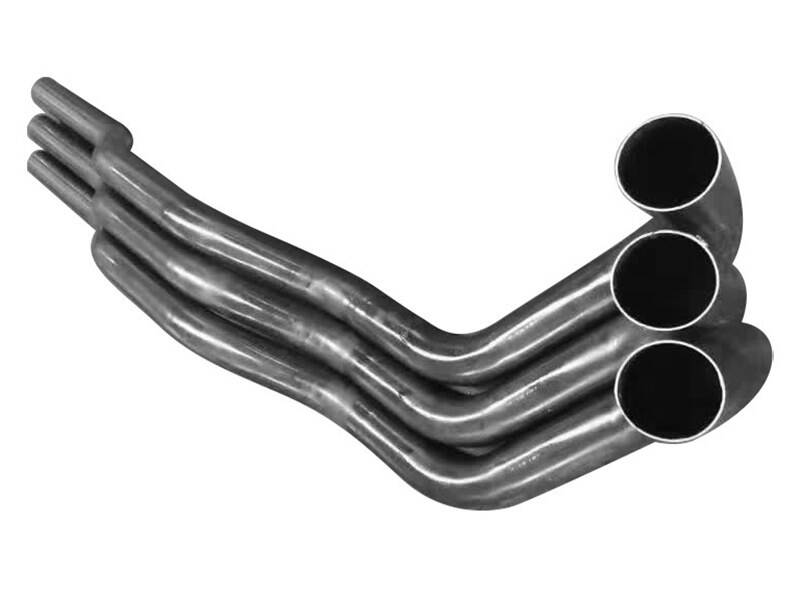

Multiple tube bending stacks

Yuetai tube benders can offer one of the highest performance solutions available in the market

CNC Full Automatic Bending Machine

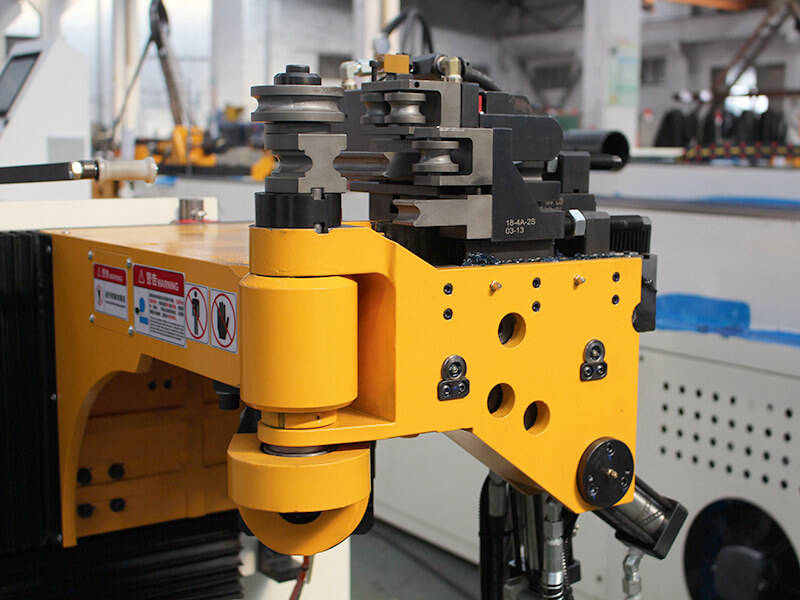

Side positioned bending head and carriage

Centralized lubrication for sliding area

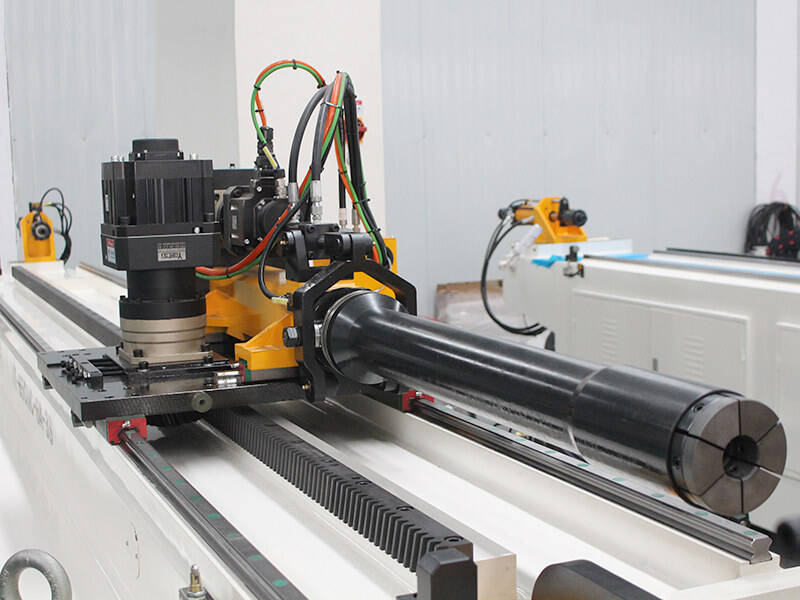

Automatic mandrel lubrication

CNC Full Automatic Bending Machine

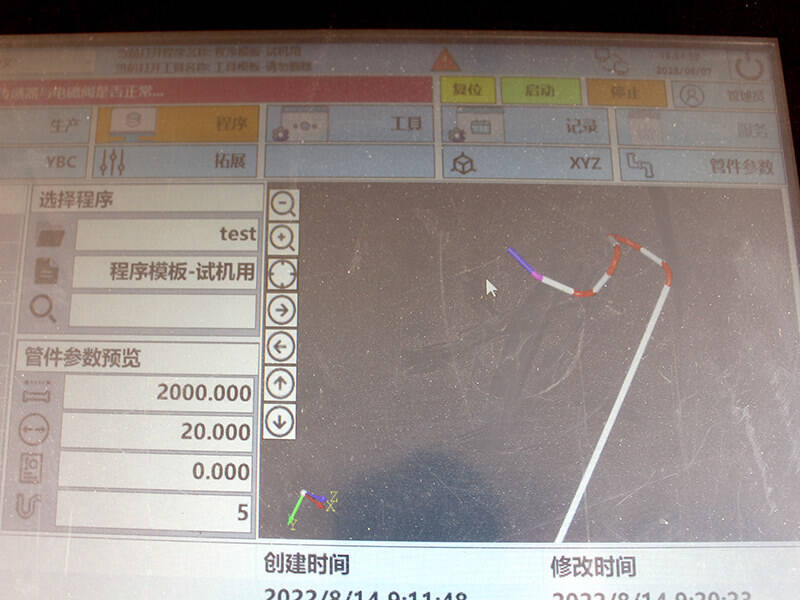

Controls software

Single or multi-stacks

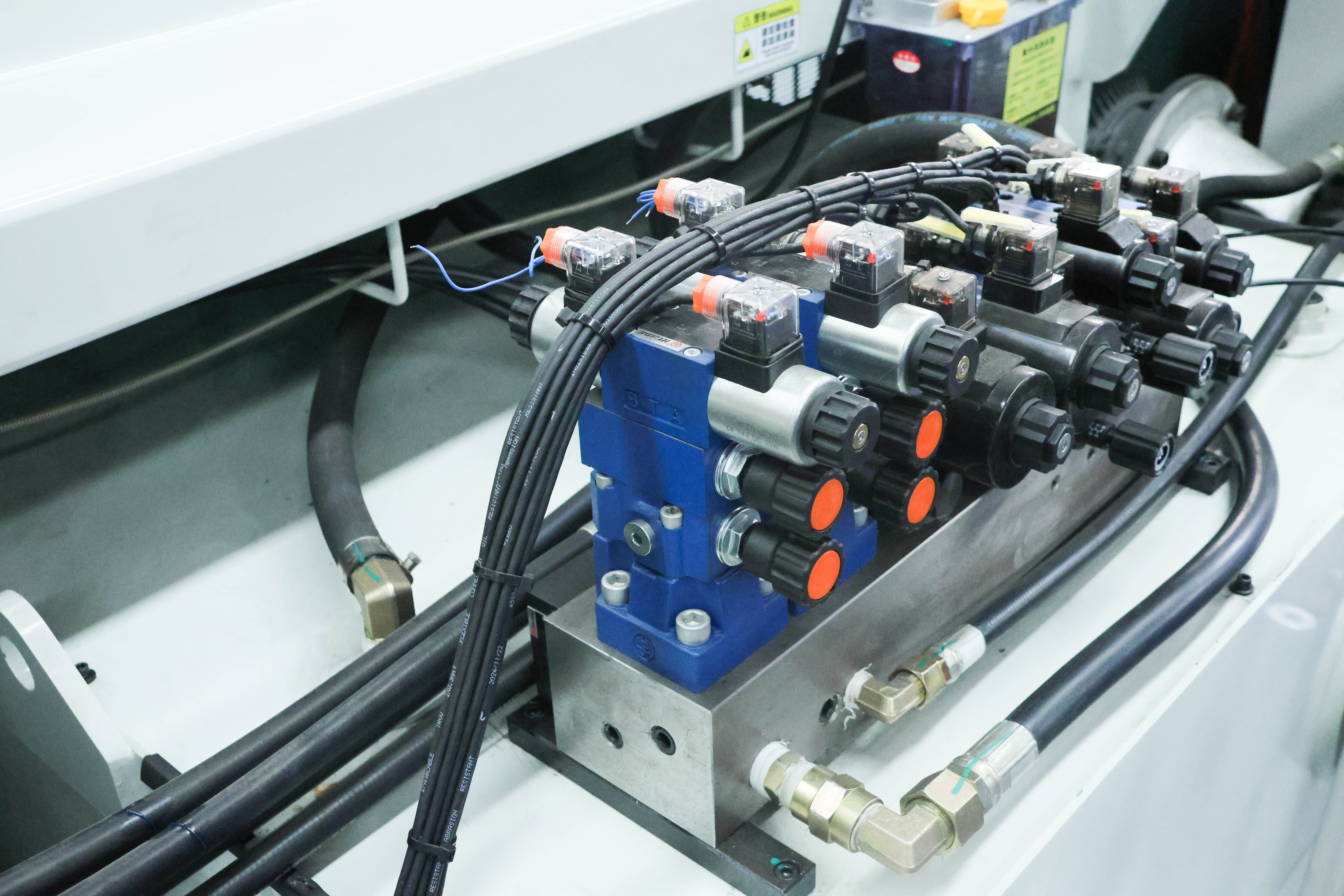

Independent pressure die system for each tube bending stack

CNC Full Automatic Bending Machine

Wiper die seat and lubrication

3D Display and Rotation of Parts

XYZ and YBC coordinates conversion

Mirroring and image reversal of parts

CNC Full Automatic Bending Machine

Fully Automatic and Cost-Effective.

This Pipe Bending line equipped with 3 programmable axes:

Feeding – Electric Servo;

Rotation – Electric Servo;

Tube Bending – Hydraulic (NC).